Your Global Automation Partner

DIGITAL INNOVATION PARK

Innovations in the field of industrial automation are emerging faster than ever before. Visit our Digital Innovation Park so you don't miss a thing. Get regular updates on a vast array of exciting trends and our latest innovations for Industry 4.0 and IIoT. It's always worth the trip! #DIGITALINNOVATIONPARK

Sustainable Digitization Solutions for the Industry

Further Topics and Highlights

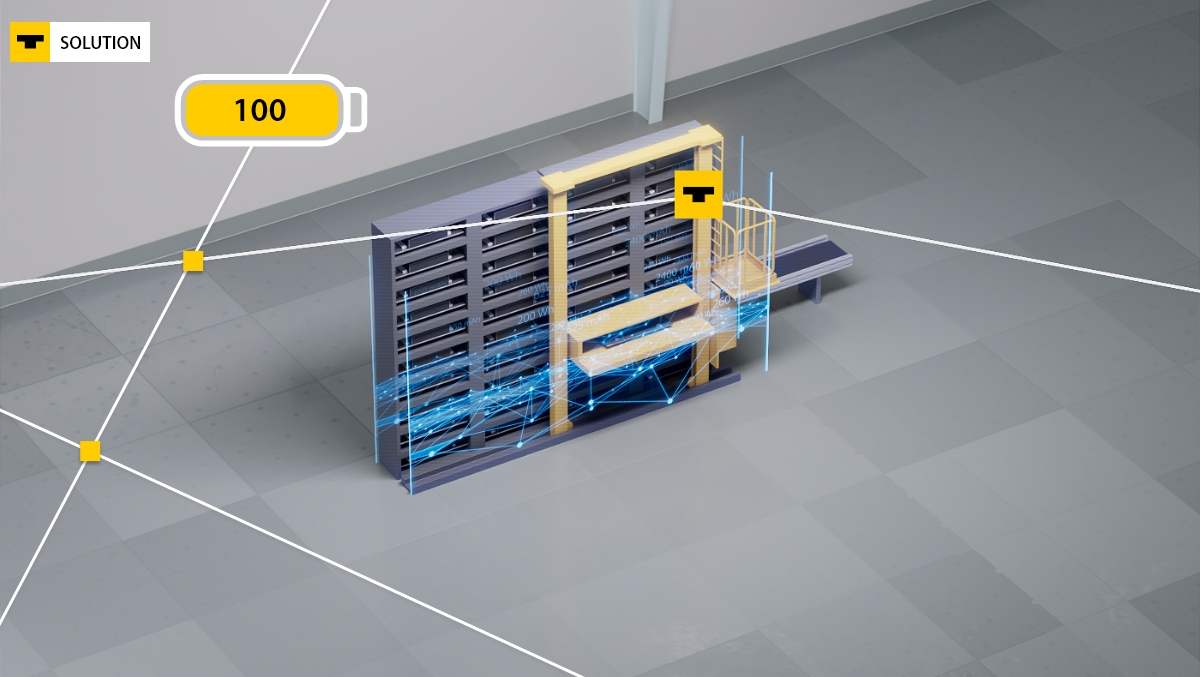

Innovative Automation for Automotive Innovation

Whatever the mobility of the future may be, Turck smart automation solutions ensure efficient and flexible production. Battery-powered electric vehicles, plug-in hybrids and fuel cell vehicles (New Energy Vehicles or NEV for short) are bringing about a profound change in the automotive industry. With customization, lightweight construction and modularization also becoming important topics, this new reality requires flexible production concepts and smart automation.

Gain Independence from Your Customers´Control Systems

Fast response to market needs and a short time to market (TTM) are key challenges of the biotechnology and pharmaceutical industry: Turck's multiprotocol Ethernet solutions help to accelerate the development, production and assembly of your plant modules. This allows you to flexibly combine a wide range of control systems with your modules and be on the market faster.

Fluid+ Sensors

Probably the Best Fluid Sensor Family for Pressure, Temperature, Flow and Level. Sounds boastful? Judge for yourself. No other automation manufacturer has developed fluid sensor technology that detects all four measured variables—flow, pressure, temperature and level—with a sensor family from a single source.

SPE and APL: Focus on Connectivity 4.0

SPE and APL will shape the future of industrial communication. The exact form this will take is currently being discussed and defined in the development departments of automation and connectivity companies. We would like to invite you to help shape the technology and to talk to us about your requirements and our solution offerings.

The Ideal Route to a Safe Machine

Decentralized safety technology creates freedom for designers through safety solutions for modular production. IP67 safety modules with integrated safety controllers eliminate the need for control cabinets and allow offline testing of safety functions for faster commissioning at the customer's site.

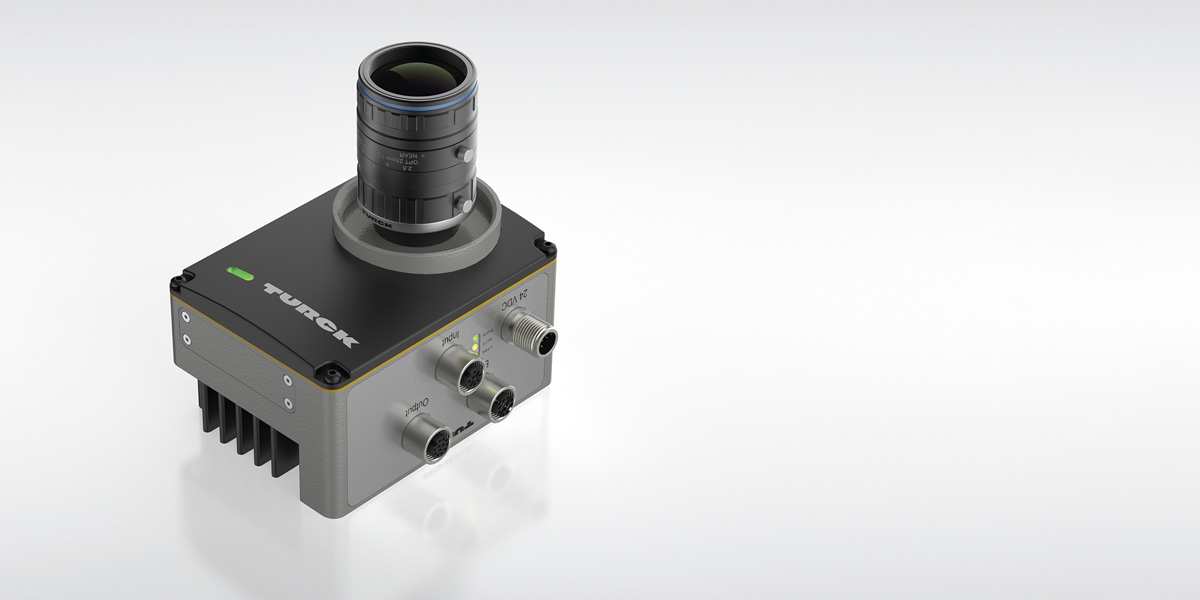

Machine Condition in View — from Day One

Turck's condition monitoring solutions for new plants detect faults before it is too late. Additional information from modern sensors and actuators is analyzed smartly, thus providing the necessary information. Find out which components enable condition monitoring.

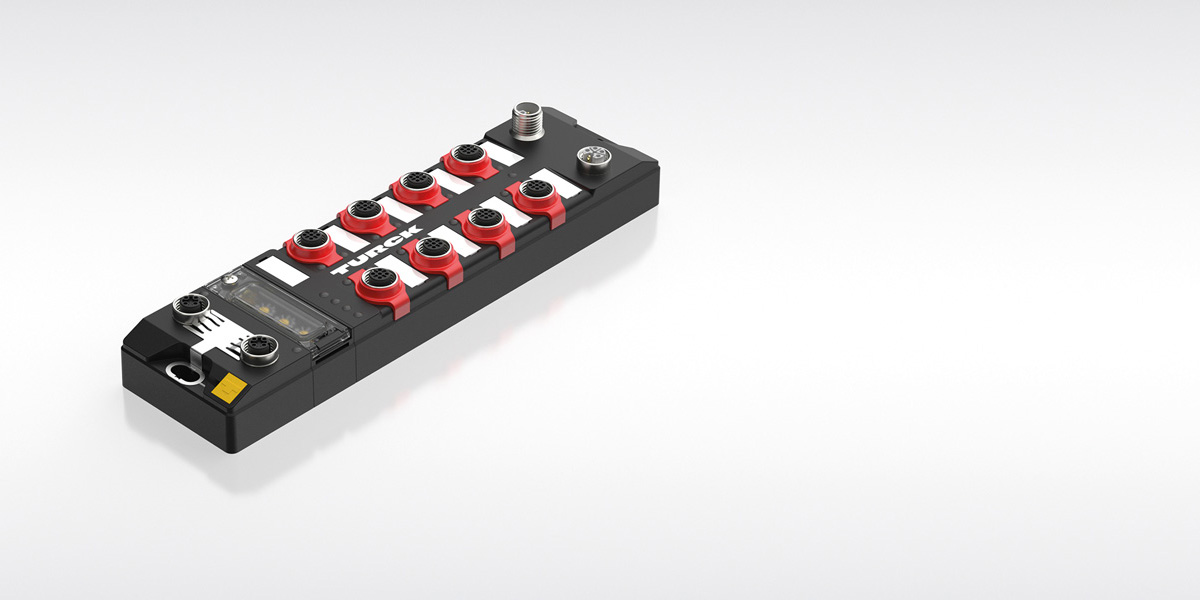

Block by Block to Flexible Intralogistics

Modular conveyor systems require powerful control solutions in the field. Turck's edge controllers and block I/O modules in IP67 make decentralized decisions about sub-processes. This not only reduces the load on the main PLC, but also accelerates commissioning.

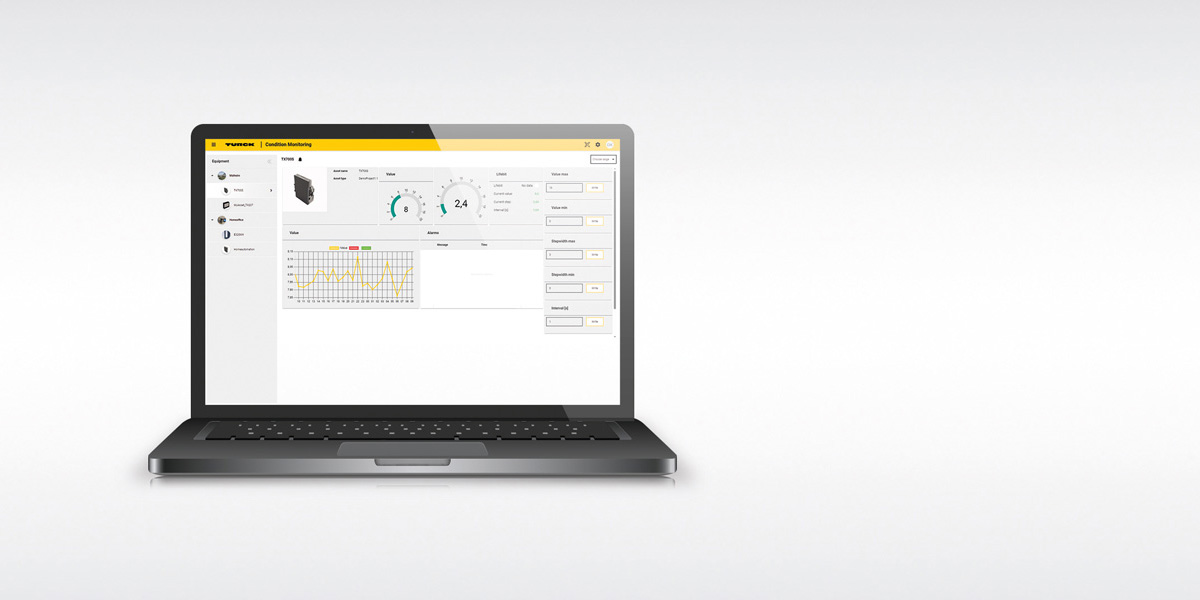

Retrofit Condition Monitoring

Autonomous systems using precise sensor technology and secure wireless networks get existing plants ready for condition monitoring. Turck's retrofit solution has no impact on running processes. Want to use data locally or send it to the cloud? The choice is yours!

Ethernet in the Ex Area

excom Ethernet allows process and status data to be transmitted and analyzed simultaneously up to zone 0 — without any intervention in existing control systems. Transfer process information alongside user data to outsourced IT systems. Get ready for intelligent condition monitoring and predictive maintenance!

The Machine Speaks: IO-Link

The bidirectional IO-Link interface is key for optimizing digital processes. Whether replacing plug-and-play sensors, diagnosing the machine or sensor status, or identifying devices, IO-Link is essential for paving the way for efficient, digital production.

Industry-optimized Cloud Services

Turck Cloud Solutions has been developed to meet the IIoT requirements of industrial customers. These requirements include encrypted communication for maximum security, plug-and-play dashboards for remote maintenance or automatic alarm messages. The perfect cloud for industrial applications — hosted by Turck or on customer-owned servers.

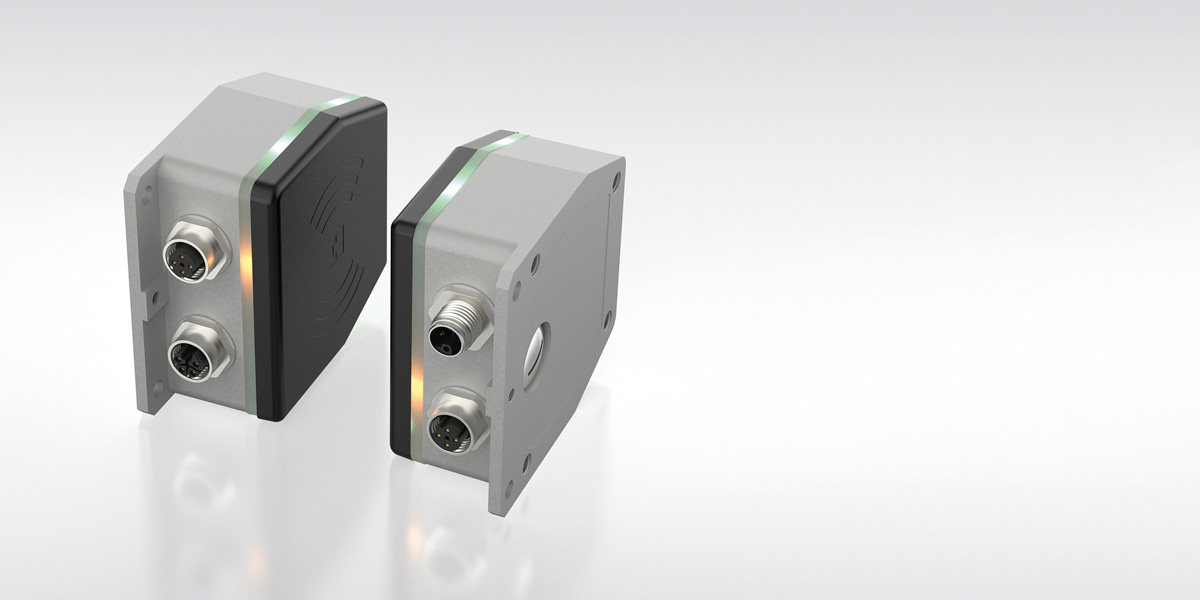

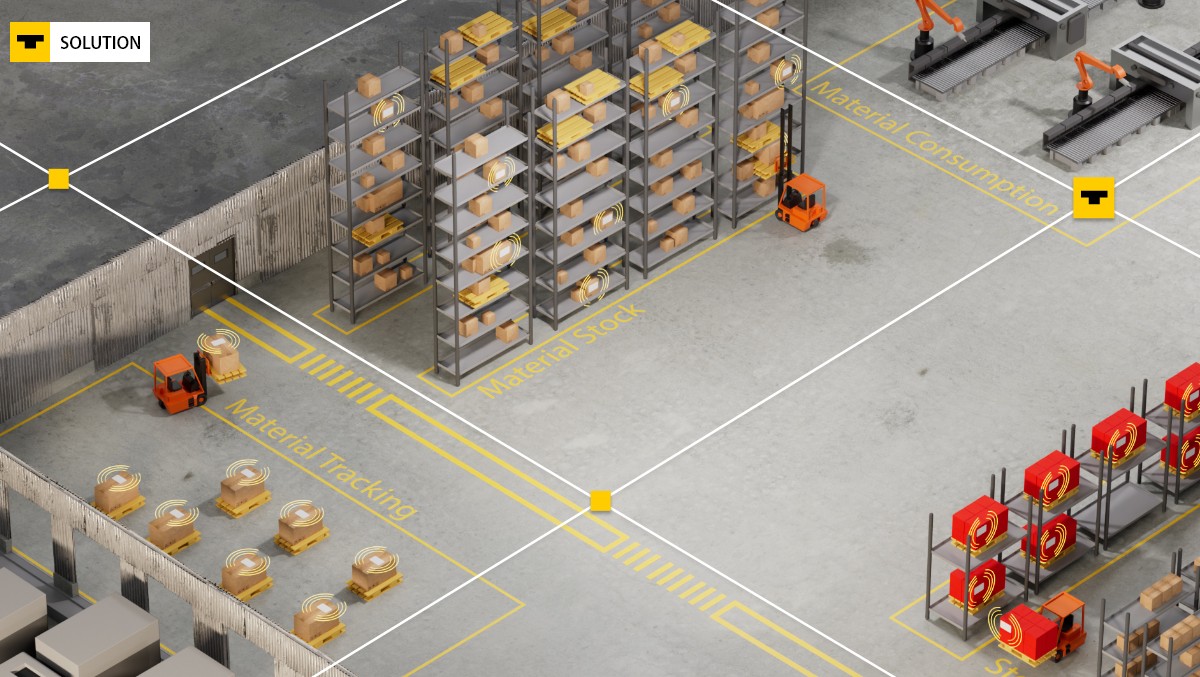

Transparency in Production and Logistics

RFID systems identify and locate goods, from goods-in and the production stage right through to retail. Turck combines its comprehensive IP67 RFID portfolio of HF and UHF technology with the integration expertise of Turck Vilant Systems, making it one of the industry's leading specialists.

Separate, Supply, Protect - Even in the Smallest Control Cabinet

The IMXK interface devices have been specially developed for installation in flat control cabinets. They are just as narrow as standard devices, but with a depth of 77 millimeters, they also fit inside compact control cabinets and other small enclosures.

High Bandwidths for Industry 4.0

The TBEN-L-SE-M2 Ethernet switch in IP67 with Gbit high-speed backbone enables the shortest link-up times and rapid data flow from I/O modules, motors and IP cameras. The switch provides maximum security through a built-in firewall, NAT routing and virtual LANs (VLAN).

Sensor Solutions – Versatile and Intelligent

Measuring position and distance or detecting objects and fluids – demanding tasks in automation require smart solutions. Turck therefore has sensors in its product range that are not only particularly robust and precise, but IO-Link empowers them to be clever all-rounders.

Smart Flow Monitoring

Delta flow monitoring and Quick-Teach make it easy to commission the FS+ flow sensor. The intuitive operating concept with capacitive buttons ensures the device is impervious up to IP6K9K without compromising on the great appearance. And thanks to the modular mechanical concept, the appropriate FS+ is available in the shortest possible time.

Find the Right One Fast: Encoders from Turck

An encoder should function in the way that best suits the application. Turck's portfolio ranges from classic efficiency encoders to premium encoders capable of taking contactless measurements. The output type and frame size, as well as the shaft type and shaft diameter are key criteria when it comes to selecting an appropriate encoder.

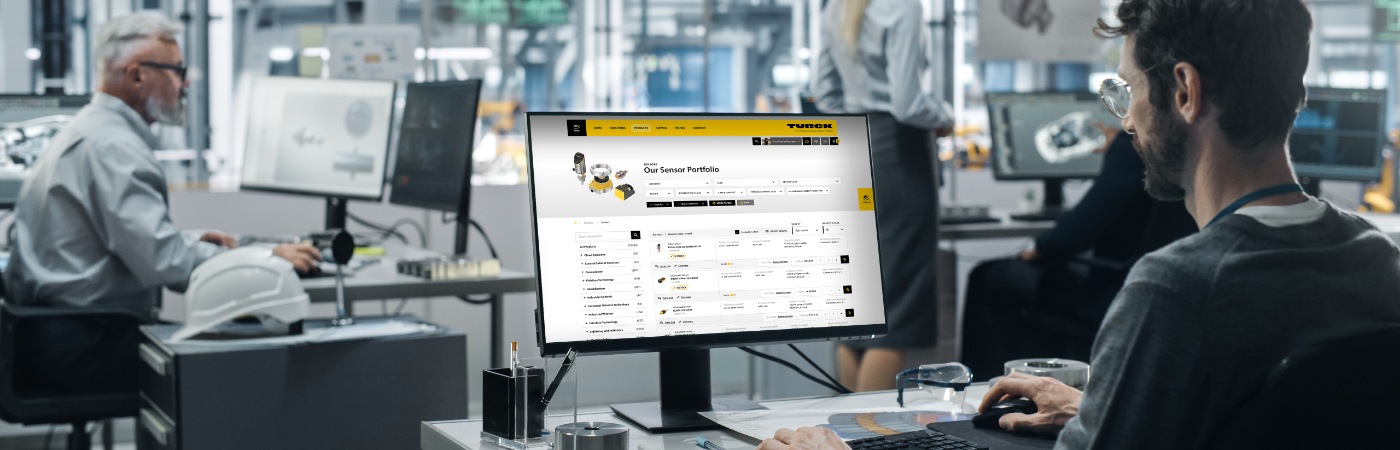

Visit our Webshop

Discover automation solutions to drive your digital transformation. Visit our Global Automation Webshop to check list prices, individual discounts, stock availability and easiest order of automation solutions. Industrial innovation starts here!

Follow us

Would you like to be regularly informed about Digital Innovation News?

Follow the hashtag on Social Media. Never miss updates on industry trends, application reports, webinars and whitepapers about smart automation.