The third generation of uprox sensors offers the most compact designs and the largest switching distances for all metals

Factor 1 Sensors of the Third Generation

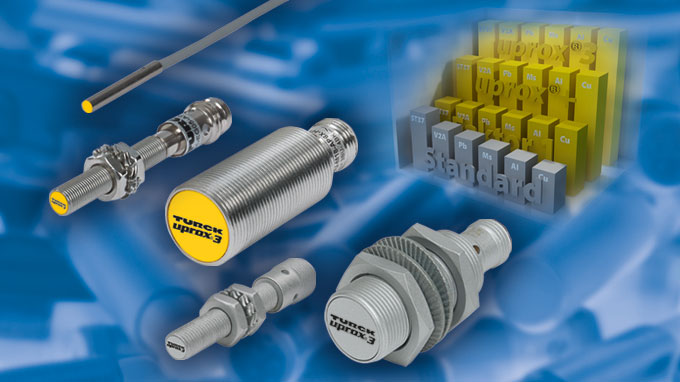

09/15 – Turck's new uprox3 series offers the most compact designs up to 4 mm in diameter and the largest switching distances for all metals

At this year's Hannover Messe, Turck is presenting uprox3 as the third generation of its range of uprox factor 1 sensor, which has the same switching distance for all metals. The electronic platform of the uprox3 Series has been completely redeveloped, and is a world first in that it enables the creation of factor 1 sensors in the compact 4 mm smooth barrel and M5 designs with a 1 mm switching distance, even for flush mounting. Turck has also managed to shorten the length of the previously most compact M8 to M18 designs.

Although the existing uprox+ sensors offered large switching distances for all metals, these could be increased by 50 percent in the new series. Turck's uprox3 Series thus currently offers the largest switching distances of all factor 1 sensors on the market; with flush mounting these are a previously unattainable 3 mm in the M8 design, 6 mm in M12 and 10 mm in M18. Thanks to the consistent further development of its uprox technology, Turck has been able to achieve these larger switching distances without any compromises in terms of performance and mounting requirements. The uprox3 sensors therefore not only offer standard application reliability for demanding switching tasks, but also allow the possibility of completely new applications.

Due to their inherent immunity to magnetic fields, the uprox3 Series sensors are suitable for use in many demanding industrial sectors such as for welding applications. Here, the new uprox3 Series once again offers especially robust PTFE coated sensors in M8, M12 and M18 designs. Like their predecessors, all uprox3 sensors offer a high EMC stability and flexible mounting options right through to fully flush mounting in all metals, as well as precise switch points.

Turck is presenting uprox3 as the third generation of its range of uprox factor 1 sensor, which has the same switching distance for all metals. The electronic platform of the uprox3 Series has been completely redeveloped, and is a world first in that it enables the creation of factor 1 sensors in the compact 4 mm smooth barrel and M5 designs with a 1 mm switching distance, even for flush mounting. Turck has also managed to shorten the length of the previously most compact M8 to M18 designs.

Although the existing uprox+ sensors offered large switching distances for all metals, these could be increased by 50 percent in the new series. Turck's uprox3 Series thus currently offers the largest switching distances of all factor 1 sensors on the market; with flush mounting these are a previously unattainable 3 mm in the M8 design, 6 mm in M12 and 10 mm in M18. Thanks to the consistent further development of its uprox technology, Turck has been able to achieve these larger switching distances without any compromises in terms of performance and mounting requirements. The uprox3 sensors therefore not only offer standard application reliability for demanding switching tasks, but also allow the possibility of completely new applications.

Due to their inherent immunity to magnetic fields, the uprox3 Series sensors are suitable for use in many demanding industrial sectors such as for welding applications. Here, the new uprox3 Series once again offers especially robust PTFE coated sensors in M8, M12 and M18 designs. Like their predecessors, all uprox3 sensors offer a high EMC stability and flexible mounting options right through to fully flush mounting in all metals, as well as precise switch points.

uprox3 IO-Link

Turck is offering uprox3 sensor also in an IO-Link-capable version. The intelligent interface makes the factor 1 inductive proximity switch a universal sensor that can be parameterized to suit over 100,000 individual requirements. For example, the two separately adjustable switching distances (each either NC or NO, as well as PNP or NPN) enable early warning functions to be set for targets subject to wear. The user can thus take action already before a failure occurs. Various timer functions can also be set, for example an off-delay for speed monitoring. These options are already possible in I/O mode, in which the sensor can be operated on a conventional digital input.

In IO-Link mode, the sensor is operated on an IO-Link master. This enables access to all parameter and evaluation functions. The intelligent data retention with IO-Link 1.1 allows a sensor to be exchanged without having to reset parameters. Already in the process data uprox3-IOL provides further analysis options such as application-specific switch points, temperature limits or an identification number. These can be used to identify 256 different nodes. The presence control of workpiece carriers or change tools and their simultaneous identification can thus be implemented with a single sensor.

Further Information

Further Information

Select Country

Turck worldwide