Easy commissioning with smart functions: Turck's capacitive sensors of the BC/UC generation

Next Generation Capacitive Sensors

Turck's capacitive IP67 sensors of the BC/UC series combine conventional operation with digital intelligence and additional data for condition monitoring

With the new BC/UC series, Turck is expanding its portfolio of capacitive sensors to meet the increasing demands for flexibility, cost efficiency and digital integration. The sensors with IP67 protection are gradually replacing existing product lines and offer cost benefits for users, particularly in high-volume applications, thanks to their platform-based development concept. The digital potentiometer with an RGB LED offers technical benefits, combining the tried-and-tested switching point adjustment using a screwdriver with direct visual feedback on the switching point – without the mechanical wear and tear or leakage risk of conventional potentiometers.

Your Benefits

- Intuitive switching point adjustment with visual feedback

- Reduces the number of variants and simplifies stockkeeping

- Fast parameterization and easy transfer to other sensors

- Cost benefits for series applications thanks to standardized architecture

Complete integration in TAS

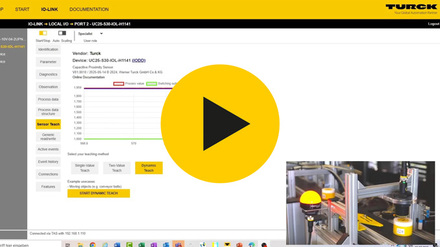

Turck will initially offer sensors with diameters of 18 and 30 mm in metal and plastic housings. The latter can be used for both flush and non-flush installation – with just one device type. The integration of IO-Link and Turck's Automation Suite (TAS) enables simple parameterization, diagnostics and commissioning. The TAS "Teach Monitor" enables sensors to be efficiently set up using different teach methods (e.g. Dynamic Teach) and parameters can be transferred to other devices – ideal for series applications.

Reliable detection even with challenging media

Besides conventional object detection, the sensors are suitable for detecting solids such as granulates and powders as well as liquids – even with difficult media such as foam or adhering substances. Other features include extended switching distances, laser-engraved housings with QR code and various connection options.

INDUSTRIES

- Packaging and conveyor technology

- Food industry

- Machine and plant building

KEY FUNCTIONS

- IO-Link with Smart Sensor Profile (SSP)

- Digital potentiometer with 360° visible RGB LED

- Extended switching distances up to 25 mm

- Laser-engraved housing with QR code

RELATED CONTENT

Tutorial: How to Teach Turck's BC/UC Capacitive Sensor Series

In this tutorial, we present two methods for teaching Turck's new BC/UC capacitive sensor series: first, by using Turck's digital potentiometer, and second, by using the Teach Monitor in Turck's Automation Suite (TAS).

Application: Capacitive Sensor Detects Point Level in Pellet Heating System

Turck Automation Suite enables convenient commissioning when the digital potentiometer of the UC/BC sensors is not accessible

Technology Page: For Everyone Wanting to Know the Details Exactly

Technical background information for condition monitoring

At a Glance: Process Optimization with IO-Link

IO-Link is essential for paving the way for efficient, digital production

Technology Page: For Those Who Want to Know More

Technical background information on the IO-Link communication standard

Technology Page: For Those Who Want to Know More

Learn more about technical background information on TAS

PRODUCT DATA

All Details about the BC/UC Capacitive Sensor Series

Approvals, data sheets, technical specifications, instructions, certificates, CAD data, and more

Data Sheets: BC/UC Capacitive Sensor Series [PDF, 2,34 MB]

Learn more about the features, technical specifications, and application details in our datasheets

Instruction of the BC/UC Capacitive Sensor Series

Find all the details on installation, commissioning, and parameterization in our instruction of use

DIGITAL SHOWCASE

Select Country

Turck worldwide